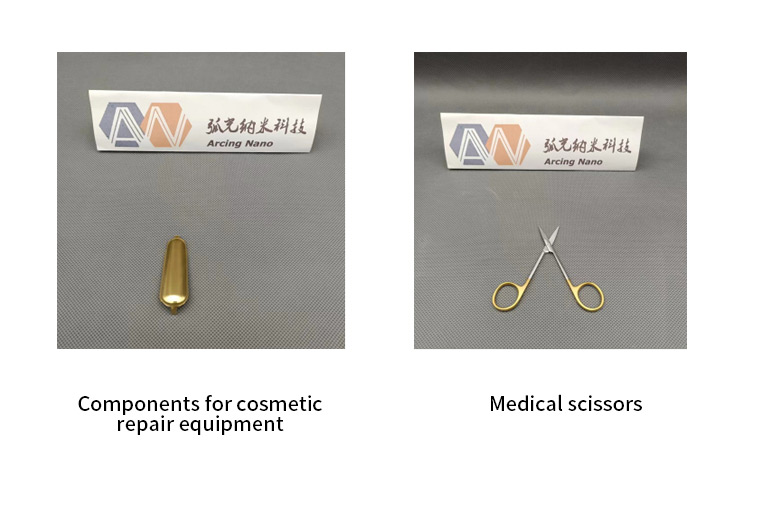

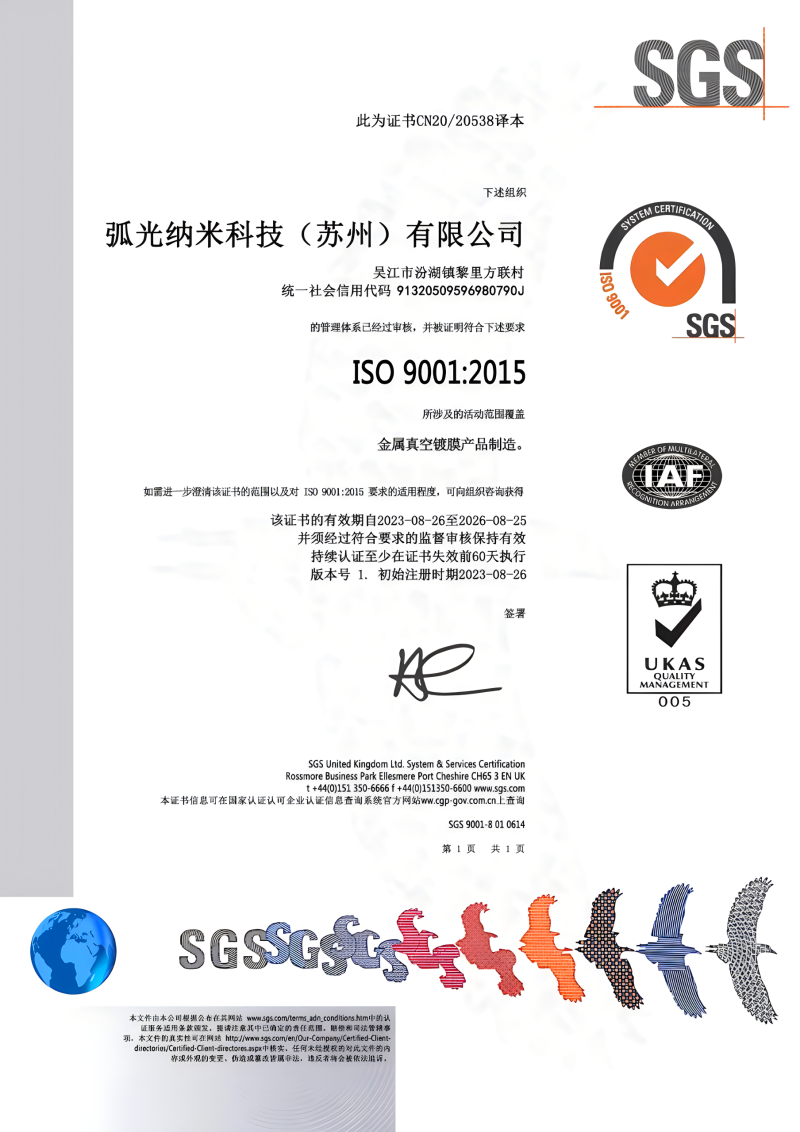

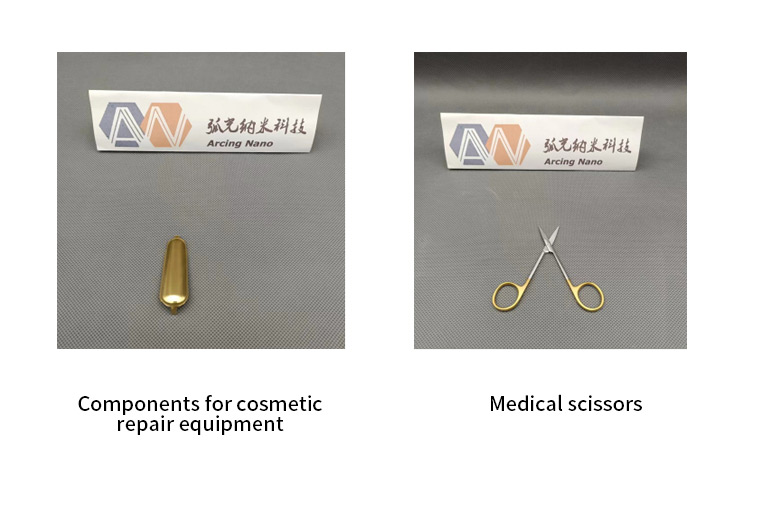

Food Medical Cosmetic Applications

PVD coatings are used in the application of moulds for food, medical and cosmetic products to improve the service life, product quality and production efficiency of the moulds by taking advantage of their properties such as high hardness, high wear resistance, low coefficient of friction and chemical stability.

PVD coating technology can effectively solve the problems of wear, adhesion and oxidation encountered during the use of moulds by forming a layer of thin film with specific functions on the surface of the mould. This coating technology is not only suitable for metal cutting tools and parts with wear-resistant requirements, but also for moulds in the food, medical and cosmetic industries.

1) TiN (Titanium Nitride) coating is a basic coating, which is widely used as a universal standard coating to prevent abrasive wear and is also widely adopted for its decorative effect.

2) CrAlN (Chromium Aluminium Nitride) coating is a composite coating with high hardness, high wear resistance, high temperature resistance and low coefficient of friction, which is widely used in die casting moulds, stamping moulds, fastener moulds, forging moulds and other industries.

(3) DLC (Diamond Like Coating) with its excellent performance - high hardness, low coefficient of friction, good chemical stability, low temperature process temperature and high densification, used in high-end mould industry, such as cosmetic packaging moulds, semiconductor molding moulds, non-ferrous metal cutting, powder metallurgy molding , automotive parts and other fields.