Component

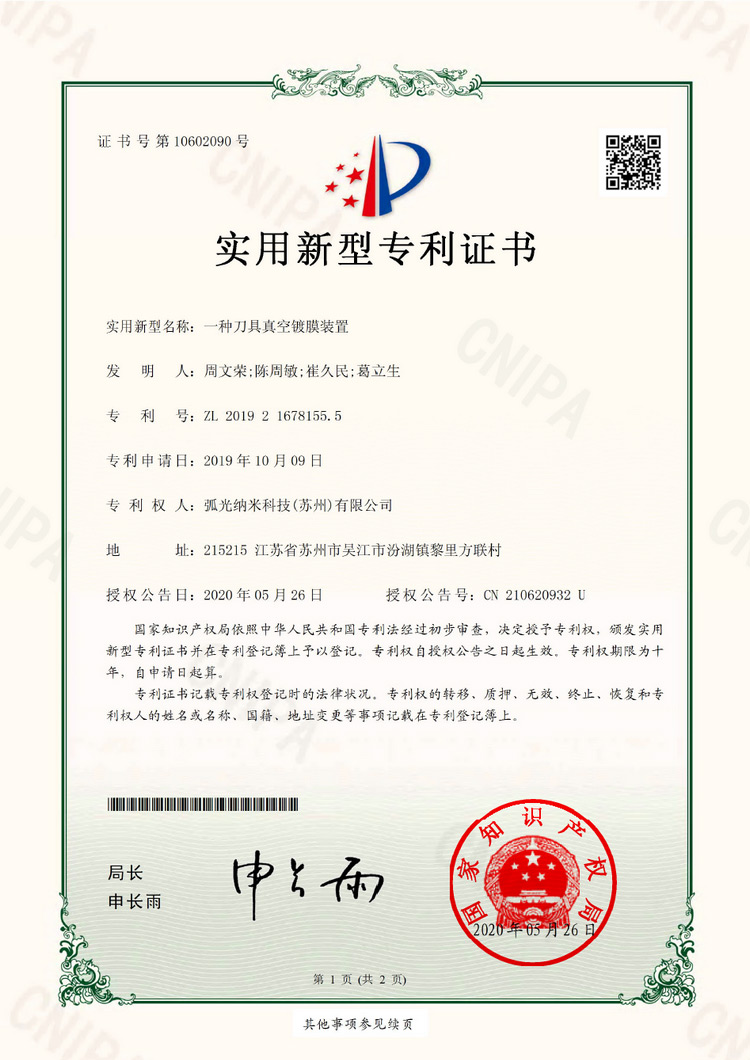

Components on household appliances can be surface treated with PVD coating technology to improve their performance and durability. This technology improves material properties, enhances surface characteristics, and improves product appearance.PVD coatings are used in a wide range of applications including, but not limited to, machined parts such as cutting tools, hobbing tools, and parts for household appliances. With PVD coatings, these parts can be treated to significantly improve wear resistance, hardness, flexural strength and impact toughness, resulting in longer service life and lower maintenance costs.

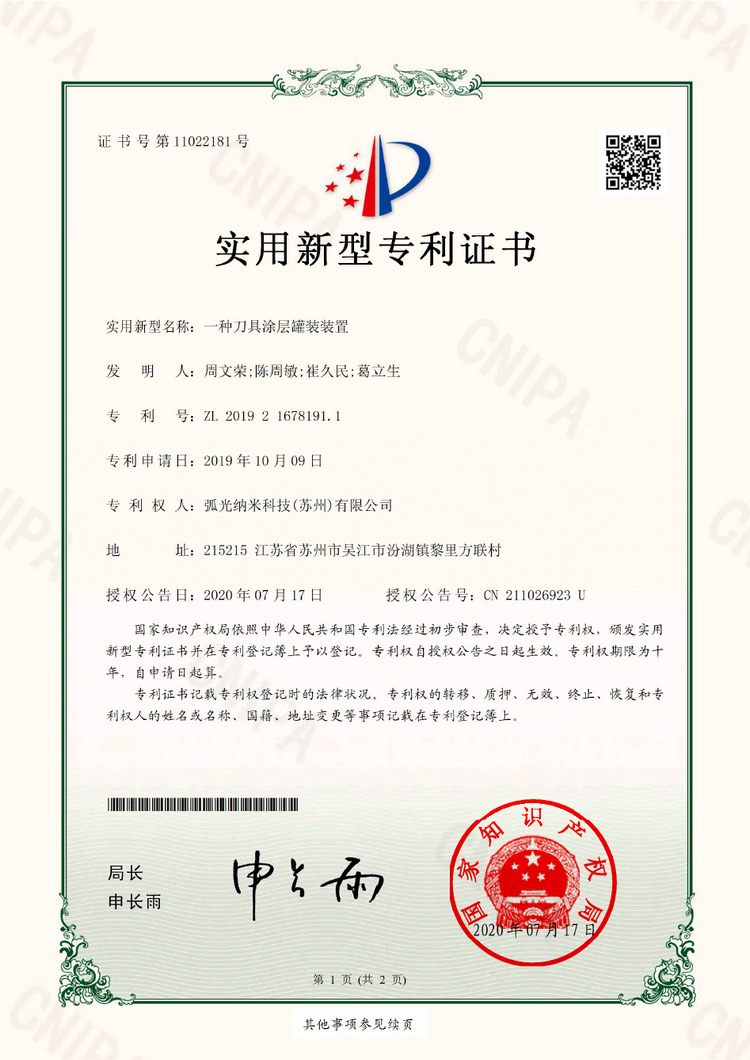

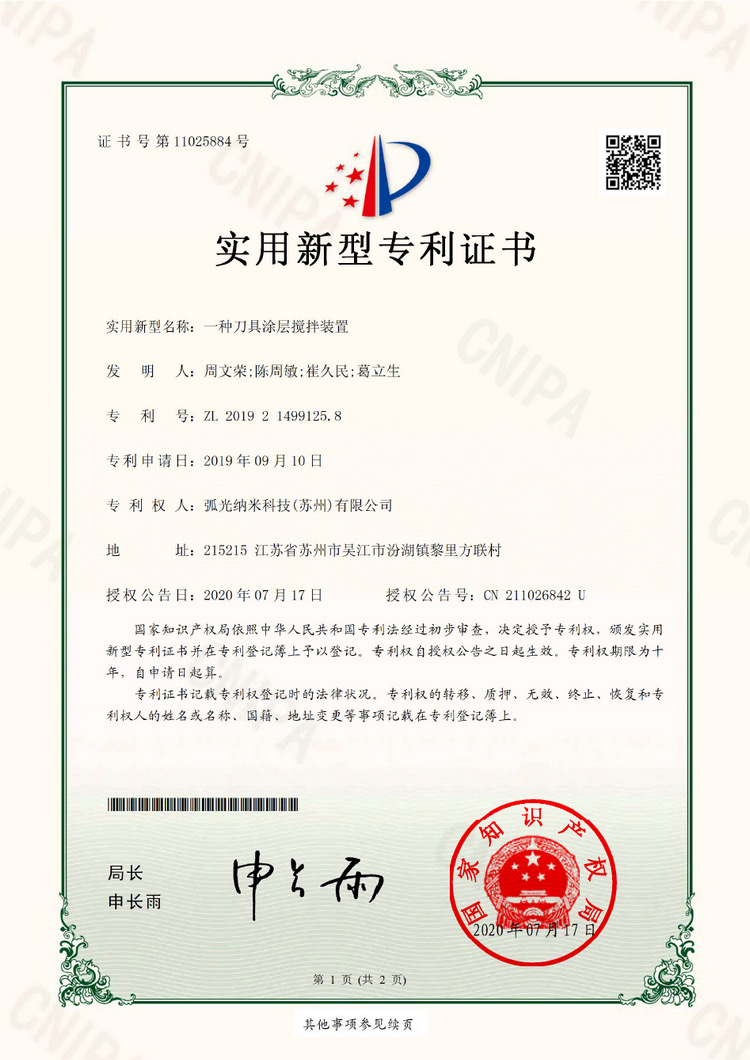

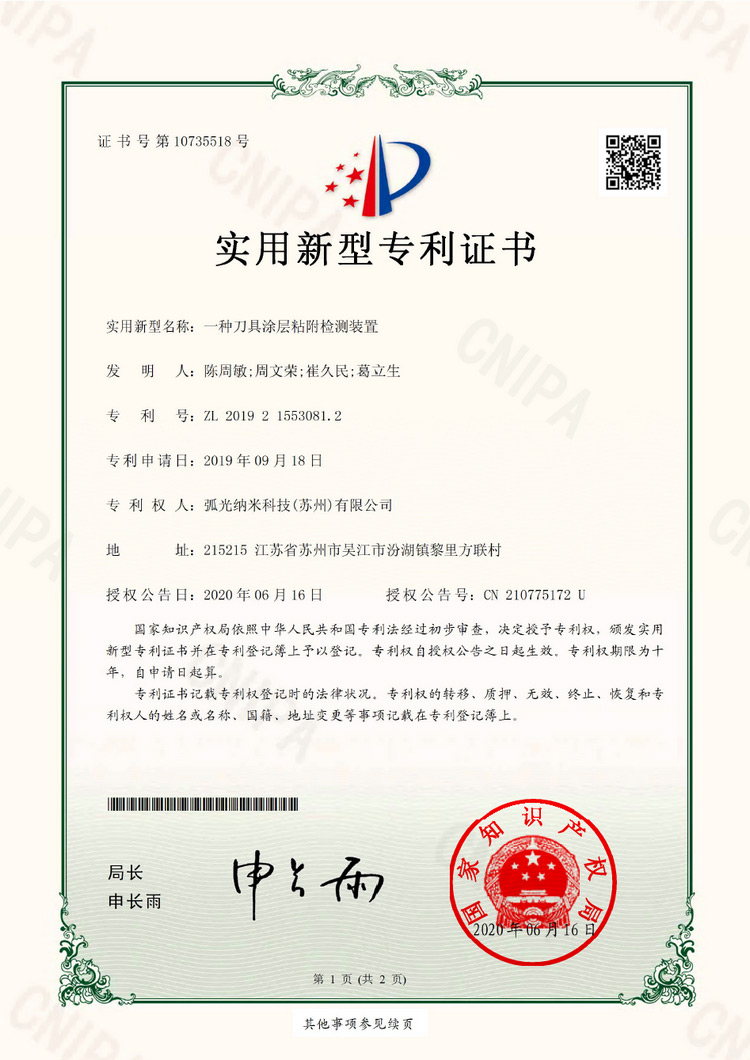

For example, some metal parts in home appliances, such as hinges and handles, can be treated with PVD coating to obtain higher corrosion and scratch resistance. This treatment not only improves the durability of the parts, but also reduces the need for protective topcoats, resulting in a more durable and elegant finish.The PVD coating process consists of steps such as cleaning, preparing the surface for coating, placing the parts in the PVD chamber for coating, and subsequent quality checks to ensure that the coating is uniform and bubble-free.

The application of PVD coating technology provides a variety of advantages for home appliance parts, including improved wear resistance, hardness, and corrosion resistance, thus enhancing the overall performance and user experience of home appliances.