It is divided into two main categories: physical vapour deposition (PVD) technology and chemical vapour deposition (CVD) technology.

1、 PVD technology including evaporation coating, sputtering coating and ion plating, etc., suitable for low temperature grass error, especially suitable for heat-sensitive materials coating, and its points include good bonding, uniform dense film and good film thickness controllability.

2、CVD technology, on the other hand, generates film materials on the surface of the substrate through chemical reactions, usually at higher temperatures, and can provide better film adhesion.

The working principle of vacuum coating machine mainly includes the following steps:

1、Creating a vacuum environment: A highly controlled vacuum environment is first created in the vacuum chamber to reduce the interference of airborne impurities on the coating process.

2、Coating process: In a vacuum environment, the film material is evaporated or decomposed into gas-phase atoms or molecules by physical or chemical means, and these atoms or molecules fly in the vacuum and deposit on the surface of the substrate to form a thin film.

3, the choice of coating materials: the selection of suitable coating materials is the key, need to consider the compatibility of the substrate as well as the function of the desired film layer, such as corrosion resistance, optical properties or electrical conductivity.

4, the kinetics and thermodynamics of film layer growth: the growth of the film layer is not only affected by the physical properties of the coating material, but also by the kinetic and thermodynamic conditions of the substrate surface.

Vacuum coating technology has a wide range of applications, from the screen protection film of mobile phones to the scratch-resistant coating of automobiles, to the efficient conversion layer of solar panels. In addition, vacuum coating technology has obvious advantages over traditional coating technology, such as the ability to prepare high-performance film layers, precisely control the thickness, composition and structure of the film layer, and provide a wide range of material selection space. Due to its environmental friendliness, vacuum coating technology is particularly important in the current requirements for environmental protection and sustainable development.

|

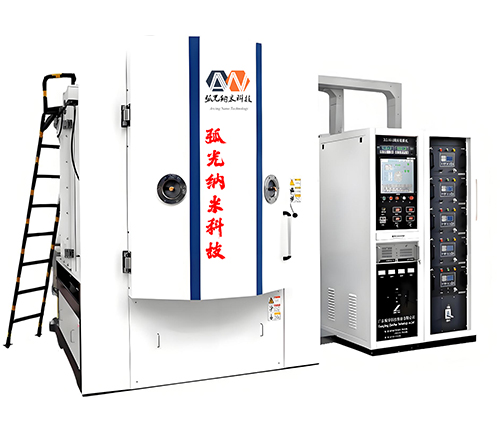

Coating Process

|

AlCrN, TIN, TICN, DLC, CrN, etc.

|

|

Etch

|

IET

|

|

Number of Arc Sources

|

8PCS

|

|

Equipment Structure

|

One-piece Construction

|

|

Equipment Specifications

|

750*1000(mm)

|

|

Gas

|

High Purity Industrial Gases

|

|

Chilled Water

|

Purified Water 3bar、5m³/h

|

|

Average Power

|

30KW·h

|

|

Energy Consumption of a Single Furnace

|

200kwh

|